LED Aluminum PCB is composed of the circuit layer (copper foil layer), thermal insulation layer and the metal core layer. Circuit layer require great current-carrying capacity, thus should use thicker copper foil and generally the thickness is from 35um to 280um; Thermal insulation layer is the core technology of aluminum PCB, it is usually made up of special ceramics and fill special polymers, with small thermal resistance, good viscoelasticity, and has thermal aging ability, and can be able to withstand mechanical and thermal stress. Thermal insulation layer of IMS-H01、IMS-H02 and LED-0601 and other high-performance aluminum PCB are using this technology, which has the extremely good thermal conductivity and high strength electrical insulation.

Metal layer is the support part of aluminum PCB, which require high heat conductivity, basically it is aluminum base, can also use copper (copper base can provide better thermal conductivity), suitable for drilling, punching, shearing, cutting and other regular mechanical processing. Surface treatment include: gold plated, HASL, OSP, Immersion gold, lead-free ROHS process, etc.

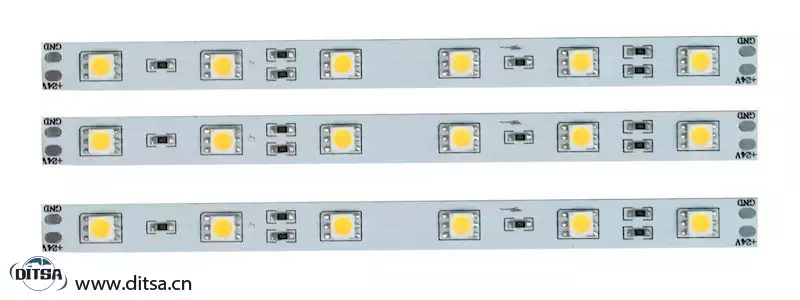

Features of aluminum PCB: thin insulation layer, low thermal resistance; Nonmagnetic; Good heat dissipation; High mechanical strength; Standard thickness: 0.8mm, 1.0mm, 1.2mm, 1.5mm, 2.0mm, 2.5mm and 3.0 mm; Copper foil thickness: 1.8um, 35um, 70um, 105um, 140um; Usage: LED dedicated, power hybrid IC (HIC).

Aluminum PCB is the carrier of heat conduction for LED and components, heat dissipation is mainly rely on area, high thermal conductivity can choose the material Bergquist.