FR4

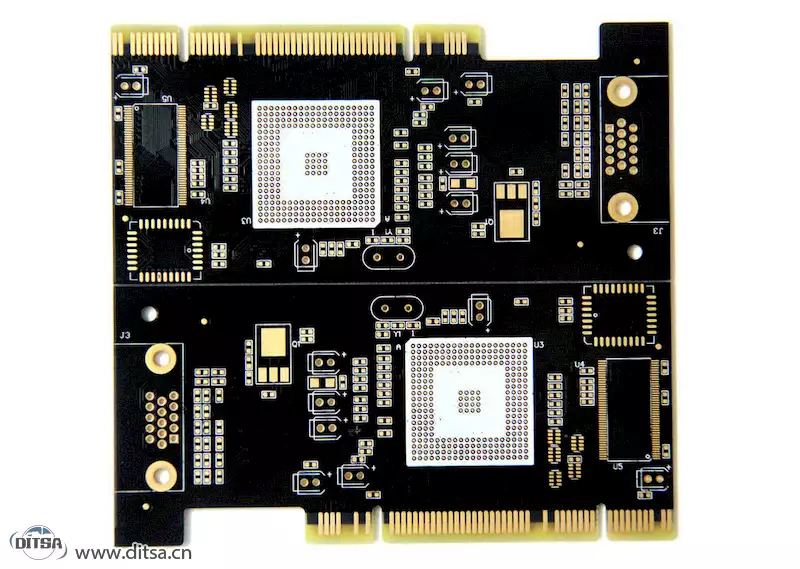

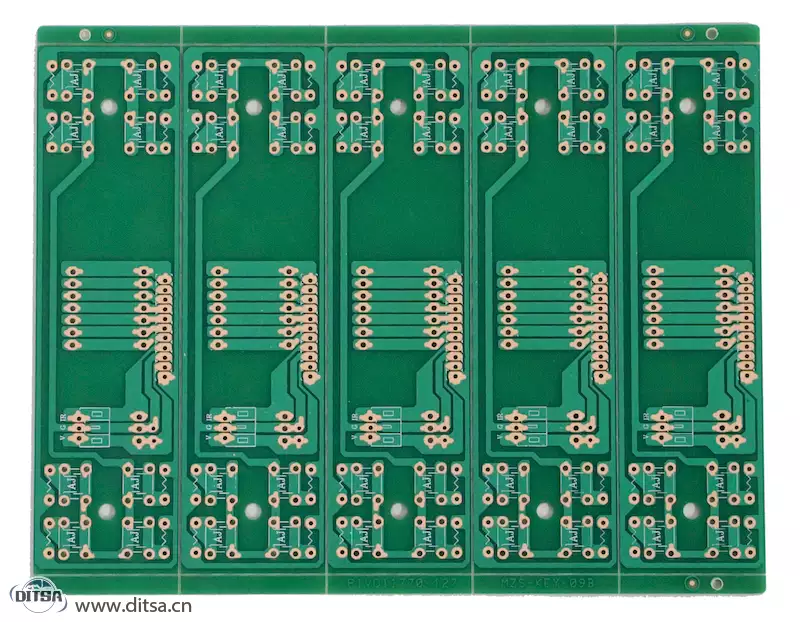

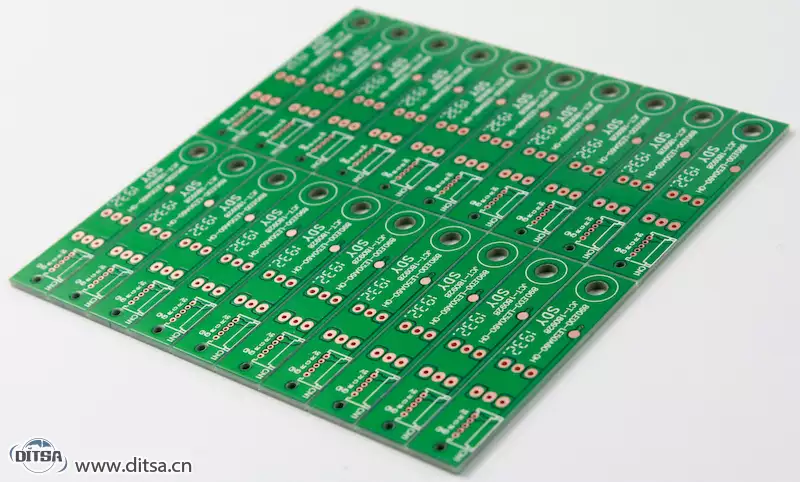

FR is for “Flame Retardant”. As a printed circuit board is made to work with electricity, it is supposed to resist heat. FR4 has a much better heat resistance than FR1/XPC thanks to a different composition of its layers. The FR4 PCB core is made of fibreglass epoxy laminate. It is the most commonly used PCB material at 1.60 mm (0.062inch) thick. The FR4 uses eight layers of glass fiber material as a standard. The maximum ambient temperature is between 120° and 130°C, depending on the brand and filler. FR1 is the cheapest option you can find but nowadays, FR4 is affordable. FR4 is the best selection in the market to make PCBs. Some materials may be cheaper but they can only be used to make one-layer boards, and the reliability of the boards made by these materials is not good. Therefore, they are only used for single-layer and very simple boards.