Rigid-flex PCB is meaning the flexible circuit board and the rigid circuit board are obtained by pressing.

The birth and development of FPC and PCB gave birth to the new product of hard and soft board. Therefore, the rigid-flex board is a circuit board with FPC characteristics and PCB characteristics, which is formed by combining flexible circuit boards and rigid circuit boards through laminating and other processes according to relevant process requirements.

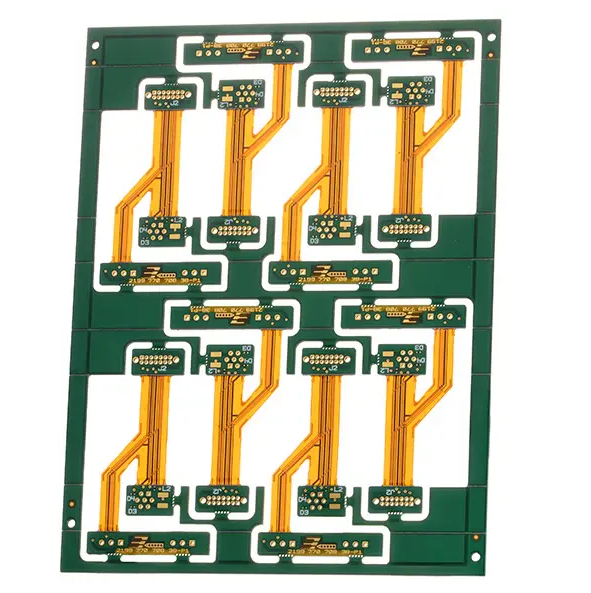

Because the Rigid-Flex board is a combination of FPC and PCB, the production of Rigid-Flex board should have both FPC production equipment and PCB production equipment. First of all, the electronic engineer draws the circuit and shape of the soft board according to the requirements, and then sends it to the factory that can produce the soft and hard board. The CAM engineer processes and plans the relevant documents, and then arranges the FPC and PCB production lines required by the FPC production line to produce PCB. After these two soft boards and hard boards come out, according to the planning requirements of the electronic engineer, The FPC and the PCB are pressed together seamlessly by a pressing machine, and then a series of details are carried out, and finally the soft and hard combination board is made. A very important link, because the combination of hardware and software board is difficult, there are many details, before shipment, it is generally necessary to carry out a full inspection, because its value is relatively high, so as not to cause the loss of related interests between the supply and demand sides.

The invention has the advantages that the soft and hard combination board has the characteristics of FPC and PCB at the same time, therefore, the soft and hard combination board can be used in some products with special requirements, has a certain flexible area and a certain rigid area, and is very helpful for saving the internal space of the product, reducing the volume of the finished product and improving the performance of the product.

Disadvantages: Hard and soft board production processes are many, production is difficult, the rate of good products is low, the input of materials, manpower is more, therefore, its price is more expensive, production cycle is longer.

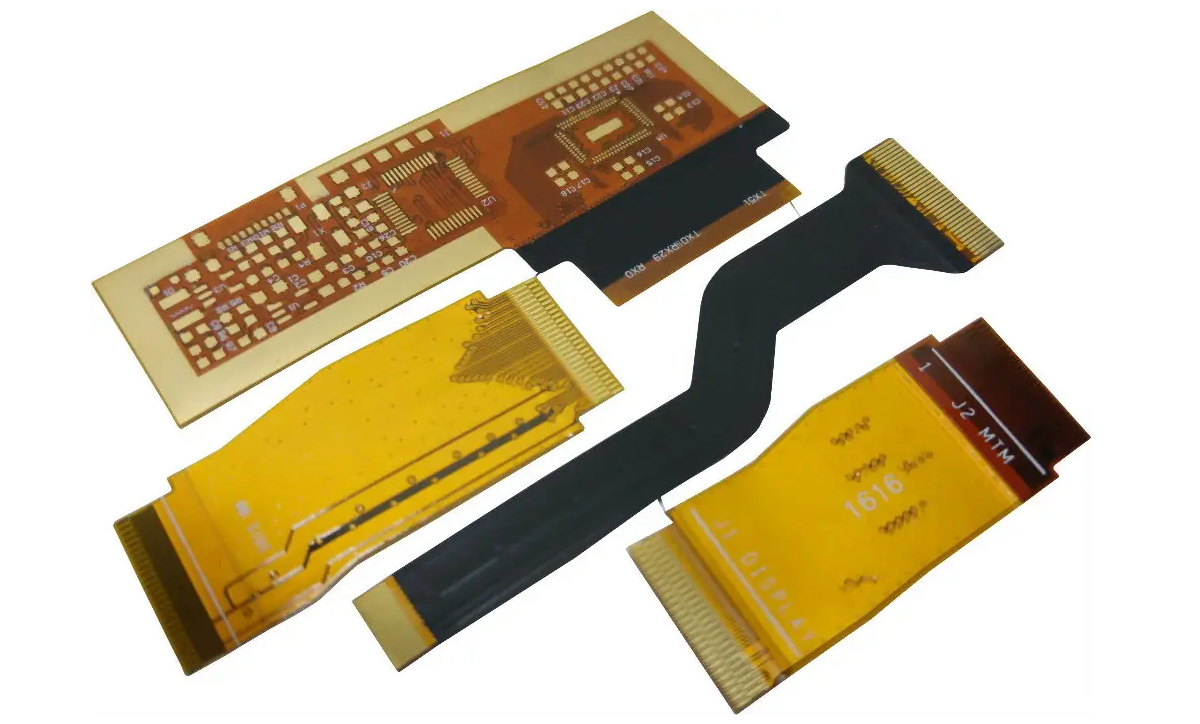

The characteristics of the Rigid-Flex board determine that its application field covers all the application fields of FPC and PCB, such as:

Mobile phone

Keypad and side keys, etc.

Computer and LCD screen Motherboard and display screen, etc.

CD Walkman Disk drive NOTEBOOK. L

atest use Constituent elements such as a suspension circuit (Su Ensi. N cireuit) of a hard disk drive (HDD, hard disk drive) and a Xe package board